Call Us08045800995

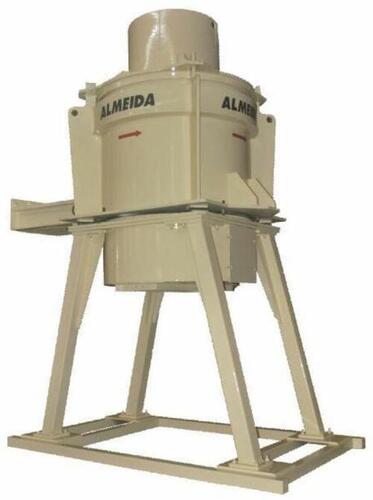

Vertical Shaft Impact Crusher

Product Details:

- Product Type Vertical Shaft Impact Crusher

- General Use Industrial

- Material Stainless Steel

- Computerized No

- Automatic Yes

- CNC Or Not Normal

- Control System PLC Control

- Click to view more

X

Vertical Shaft Impact Crusher Price and Quantity

- 1 Unit

Vertical Shaft Impact Crusher Specification

- Industrial

- Brown

- No

- Vertical Shaft Impact Crusher

- Normal

- Yes

- PLC Control

- Stainless Steel

- High Performance Low Noise ECO Friendly High Efficiency Lower Energy Consumption

Vertical Shaft Impact Crusher Trade Information

- 10 Unit Per Month

- 1-3 Week

- All India

Product Description

Buy from us a highly efficient and productive Vertical Shaft Impact Crusher that is installed with a highly robust grinder to transform rocky substances into fine free-flowing granular forms. It is equipped with a high-speed electric motor that is capable to run efficiently for a longer period without any risk of damages. The whole unit is mounted on a rigid four-legged support that gives high durability and stability. It is also provided with an inlet hopper to safely transport feed materials to the processing chamber.

Applications of Vertical Shaft Impact Crushing Machine:

1. Aggregate Production: VSI crushers are widely used for producing high-quality cubical aggregates for road construction, concrete production, and asphalt mixing. They can efficiently shape the coarse and fine aggregates, making them ideal for use in various construction projects.

2. Mining and Minerals Processing: VSI crushers are used in the mining and minerals processing industries to crush and shape various types of hard, abrasive, and non-abrasive materials. They are particularly effective in processing ores and minerals such as iron ore, copper ore, gold ore, and diamond-bearing ore.

3. Manufactured Sand Production: VSI crushers are used to produce high-quality manufactured sand (M-sand) from quarried stone or rocks. M-sand is an alternative to natural river sand and is used in concrete production and other applications where natural sand availability is limited.

4. Recycling: VSI crushers can be used in recycling applications to process construction and demolition (C&D) waste, concrete, and asphalt recycling. The crushers can reduce the waste material to a desired size and shape, making it suitable for reuse in construction projects.

5. Industrial Minerals Processing: VSI crushers are used in various industrial minerals processing applications, such as producing glass and ceramics, manufacturing silicon carbide, and preparing raw materials for the production of cement.

6. Oil and Gas Well Drilling: In the oil and gas industry, VSI crushers are used for crushing and shaping rocks and minerals during the drilling process. The crushed material acts as a proppant, helping to keep the fractures open to improve oil and gas recovery.

7. Quarrying and Stone Crushing: VSI crushers are used in quarrying activities to produce aggregates and crushed stones. They help in shaping the final products and improve the overall quality of the material.

8. Fertilizer and Chemical Production: VSI crushers are used to crush and shape raw materials in the fertilizer and chemical manufacturing industries. They can efficiently process materials like phosphate, potash, and other fertilizers.

9. Construction and Infrastructure Development: VSI crushers play a crucial role in construction projects by producing high-quality aggregates that meet specific requirements for strength and durability.

FAQ:

Q. What is a Vertical Shaft Impact Crusher (VSI)?

Ans: A Vertical Shaft Impact Crusher, commonly known as VSI, is a tertiary or quaternary stage crushing equipment used to make artificial sand, produce high-quality cubical aggregates, and shape various hard and abrasive materials. It operates by accelerating the feed material to high speeds and then propelling it against a crushing chamber's walls, breaking it into smaller pieces.

Q. How does a VSI crusher work?

Ans: A VSI crusher works by feeding the material into a center rotor, which then flings the material against the outer walls of the crushing chamber. This high-speed impact causes the stones or ores to break into smaller, more uniform pieces. The crushed material then exits through the bottom of the crusher.

Q. What are the advantages of VSI crushers?

Ans: Some of the advantages of VSI crushers include:

- Ability to produce cubical-shaped end products.

- Efficient crushing of various materials, including hard and abrasive ones.

- Low operating and maintenance costs.

- Versatility in applications, from aggregate production to industrial minerals processing.

Q. What types of materials can be crushed using VSI crushers?

Ans: VSI crushers are suitable for crushing a wide range of materials, including but not limited to:

- Rocks and ores (e.g., granite, limestone, basalt, iron ore, etc.).

- Industrial minerals (e.g., silica sand, glass cullet, etc.).

- Construction and demolition waste.

- Concrete and asphalt recycling materials.

Q. Can VSI crushers be used for primary crushing?

Ans: VSI crushers are primarily used for tertiary and quaternary crushing stages, which means they are suitable for crushing materials after the primary and secondary crushing processes. They are not typically used as primary crushers.

Q. How is the product size controlled in a VSI crusher?

Ans: Product size in a VSI crusher is controlled by varying the rotor speed, the size and shape of the feed material, the anvils' configuration, and the operating parameters. Adjusting these factors can influence the final product size and shape.

Q. Are VSI crushers suitable for mobile applications?

Ans: Yes, VSI crushers can be used in mobile crushing plants. Their compact and modular design allows for easy integration into mobile platforms, making them suitable for various mobile applications.

Q. What maintenance is required for VSI crushers?

Ans: Regular maintenance of VSI crushers includes checking and replacing wear parts such as the rotor tips, anvils, and distributor plates. Additionally, monitoring and adjusting the crusher's operating parameters to optimize performance and efficiency is essential.

Q. Are VSI crushers environmentally friendly?

Ans: VSI crushers can be more environmentally friendly compared to some traditional crushing methods, particularly when used for producing manufactured sand from crushed stone. Since they do not require water for material shaping, they can reduce the environmental impact associated with sand production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free