Call Us08045800995

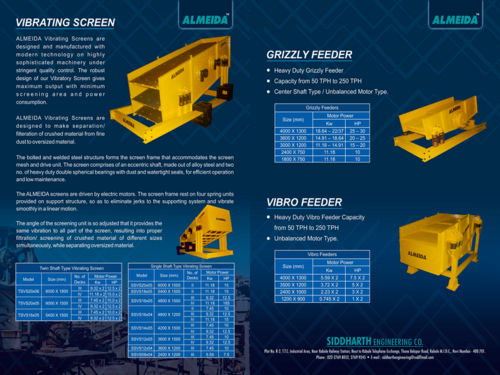

Vibrating Screen

Product Details:

- Color Yellow

- Size Standard

- Type Vibrating Screen

- Material Stainless Steel

- Condition New

- Power Mode Electric

- Click to view more

X

Vibrating Screen Price and Quantity

- 1 Unit

Vibrating Screen Specification

- Yellow

- Vibrating Screen

- Standard

- Electric

- New

- Stainless Steel

Vibrating Screen Trade Information

- 15 Unit Per Month

- 7-15 Days

- All India

Product Description

Vibrating Screen Machine is required for grading of raw materials into uniform particle sizes with the help of circular motion of an unbalanced flywheel. It is completely suitable to be used with sand making machines for removing large stones from crushed powder. This screen is powered by a heavy duty motor which generates controlled amount of vibration as set by user. Its frame has been fabricated using superior quality cast iron with paint coated surface for ensuring good structural strength & durability. Vibration Screen Machine has also been equipped with strong springs that add synergistic effect to motor, resulting in more grading efficiency.

Uses of Vibrating Screen Machine:

1. Material Sorting: Vibration screen machines are commonly used to sort and classify bulk materials based on their particle size. This is particularly useful in industries like mining, quarrying, construction, and agriculture, where different materials need to be separated according to their size.

2. Particle Size Classification: In industries such as pharmaceuticals, food processing, and chemical manufacturing, vibrating screens are used to classify particles according to their size ranges. This helps ensure uniformity and consistency in the final products.

3. Dewatering: Vibration screens can be used to remove excess water from materials, such as in the mining and aggregate industries. This process is known as dewatering and is essential for efficient material handling and transport.

4. Grading and Sizing: The screens can be used to grade and size materials according to specific requirements. For instance, in the agriculture industry, grains are often graded using vibrating screens to meet quality standards.

5. Cleaning and Separation: In recycling and waste management, vibrating screens are employed to separate different materials, ensuring that valuable resources can be reclaimed and reused.

6. Safety Screening: In the pharmaceutical and food industries, vibrating screens are used for safety screening to remove any oversized or foreign particles from the final products.

7. Scalping: Vibrating screens are used for scalping, which means removing the coarsest particles before further processing. This is common in the mining and quarrying industries.

8. De-dusting: In industries that handle dusty materials, such as minerals and chemicals, vibrating screens can be used to remove dust and improve air quality.

9. Washing: Vibration screens can be part of a washing process, where they separate particles based on size and remove impurities from the material being washed.

10. Recycling: Vibrating screens are used in recycling processes to separate recyclable materials from non-recyclables, aiding in waste management and resource conservation.

FAQ:

Q. What is a vibrating screen machine?

Ans: A vibrating screen machine is a device that uses a vibrating motor to generate vibrations, which causes materials to move across the screen and be separated or classified based on their particle size.

Q. What are the main uses of vibrating screen machines?

Ans: Vibrating screen machines are used for material sorting, particle size classification, dewatering, grading and sizing, cleaning and separation, safety screening, scalping, de-dusting, washing, and recycling across various industries.

Q. How does a vibrating screen machine work?

Ans: The vibration screen machine consists of a vibrating motor, screen deck, and supporting structure. When the motor is powered on, it generates vibrations that cause the material to move on the screen. Larger particles stay towards the top, while smaller particles pass through the screen openings and collect at the bottom.

Q. What are the different types of vibrating screen machines?

Ans: There are several types of vibrating screen machines, including circular vibrating screens, linear vibrating screens, high-frequency vibrating screens, and inclined vibrating screens. Each type has specific applications and advantages.

Q. What factors should be considered when selecting a vibrating screen machine?

Ans: Factors to consider include the material's properties (e.g., size, density, moisture), required capacity, desired separation efficiency, screen aperture size, and the specific industry and application.

Q. How do I maintain a vibrating screen machine?

Ans: Regular maintenance is essential to ensure the machine operates efficiently. This includes checking for wear and tear, lubricating moving parts, tightening bolts, and inspecting the screen mesh for damage or blockages.

Q. Can vibrating screen machines handle wet materials?

Ans: Yes, vibration screen machines can handle wet materials. However, some designs are more suitable for wet applications, as they incorporate features for efficient dewatering and liquid-solid separation.

Q. Are vibrating screen machines customizable?

Ans: Yes, vibrating screen machines can be customized to suit specific needs. Manufacturers can adjust the screen size, angle of inclination, vibration amplitude, and other parameters to optimize performance for various materials and applications.

Q. How do I prevent screen blinding or blockage?

Ans: Screen blinding occurs when particles get stuck in the screen openings, reducing screening efficiency. To prevent blinding, you can use self-cleaning screens, screen cleaning devices, or select a screen mesh suitable for the material being processed.

Q. Can vibrating screen machines be used in hazardous environments?

Ans: In certain cases, vibrating screen machines can be designed to meet safety and environmental requirements for hazardous or explosive materials. It's essential to work with manufacturers who can provide appropriate safety measures and certifications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free